Modern Techniques in CNC Swiss Machineing

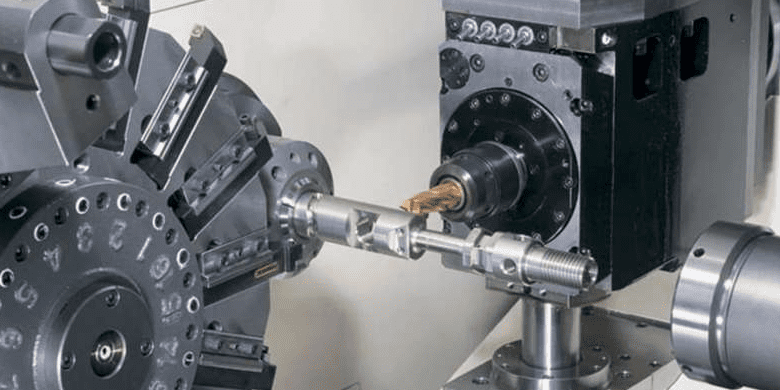

Introduction to CNC Swiss Machineing

CNC swiss machineing is a highly precise manufacturing process used for producing small and complex components. It is different from traditional turning methods because the workpiece is supported close to the cutting tool, reducing vibrations and improving accuracy. Industries such as medical, aerospace, electronics, and automotive heavily rely on this technology for parts requiring exact tolerances and intricate designs.

Key Components of CNC Swiss Machineing

Sliding Headstock Mechanism

The sliding headstock allows the material to move in sync with the cutting tool, preventing deflection and ensuring precise machining. This component is essential for producing long, thin, or intricate parts.

Multi-Axis Functionality

Modern CNC swiss machines often include multiple axes, enabling simultaneous operations such as turning, drilling, and milling. This reduces the need for multiple setups and increases production efficiency.

Automated Tooling Systems

Automated tool changers in CNC swiss machines allow continuous production without manual intervention. This reduces human error and supports high-volume manufacturing with consistent quality.

Advantages of CNC Swiss Machineing

Superior Accuracy

The close support of the material ensures exceptional precision for even the smallest components, making it ideal for medical implants, aerospace parts, and other critical applications.

Increased Efficiency

By combining multiple operations in a single setup, cnc swiss machineing minimizes production time and reduces handling requirements. This efficiency is valuable for both low and high-volume production runs.

Material Versatility

CNC swiss machineing can handle a wide range of materials, including stainless steel, aluminum, titanium, brass, and some plastics, making it suitable for diverse industrial applications.

Cost-Effective Manufacturing

Though the initial investment can be high, reduced scrap, fewer errors, and faster production cycles make cnc swiss machineing a cost-effective solution in the long term.

See also: Insurance Singapore: Choosing the Right Coverage for Your Needs

Selecting the Right Provider

Experience Matters

Choosing a provider with years of experience ensures that the machining process is optimized for quality, speed, and accuracy. Experienced technicians can manage complex designs and material specifications effectively.

Advanced Equipment

Providers with modern, multi-axis CNC swiss machines and digital control systems are better equipped to deliver high-precision components efficiently.

Quality Assurance Practices

Reliable providers implement strict quality control measures to maintain consistent standards across all components, ensuring that parts meet industry requirements.

Adaptability

A skilled provider can handle urgent orders, design modifications, and high-volume production without compromising quality. Flexibility is critical in modern manufacturing.

Applications Across Industries

Medical Sector

CNC swiss machineing is widely used to manufacture surgical instruments, implants, and other medical components that demand tight tolerances.

Aerospace Industry

High-precision aerospace components such as turbine parts and structural elements benefit from the accuracy and reliability of cnc swiss machineing.

Automotive Manufacturing

Engine parts, fuel system components, and other precision CNC swiss machineing automotive elements are efficiently produced using CNC swiss machines.

Electronics Components

Miniature electronic parts like connectors and housings are manufactured with high accuracy, ensuring reliability in compact and sensitive designs.

Emerging Trends

Integration with Automation

Combining robotic systems with CNC swiss machineing enhances productivity, reduces manual labor, and maintains high quality in large-scale production.

Hybrid Manufacturing Techniques

Combining CNC swiss machineing with additive manufacturing enables complex geometries while reducing material waste and production time.

Sustainability Practices

Energy-efficient machines and environmentally friendly materials are increasingly adopted, aligning precision manufacturing with sustainable goals.

Digital Simulation

Digital twins and process simulation software allow manufacturers to optimize machining operations, reducing errors and improving overall efficiency before production starts.

Conclusion

CNC swiss machineing is a crucial technology for producing precise, complex components across multiple industries. Its advantages include exceptional accuracy, efficiency, and material versatility. Selecting an experienced provider with modern equipment and rigorous quality control ensures reliable production. With ongoing advancements, cnc swiss machineing continues to be integral to innovation and high-precision manufacturing, benefiting sectors like medical, aerospace, automotive, and electronics.