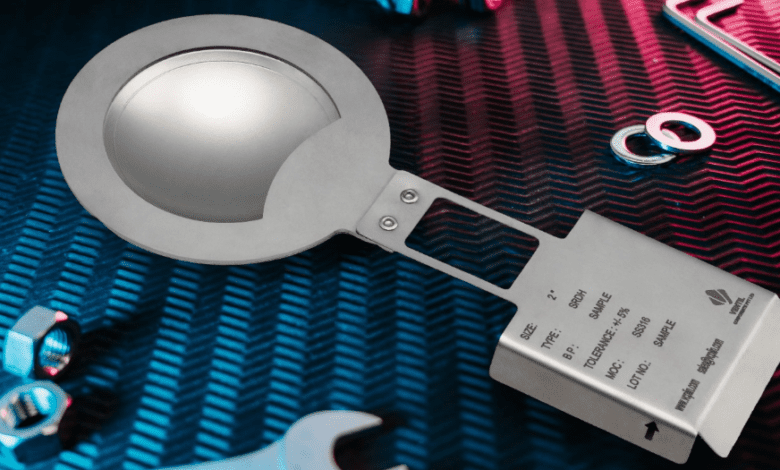

Understanding the Importance of Rupture Disk Valves

In modern industrial applications, pressure management is a critical safety consideration. Devices like rupture disk valves are specifically designed to protect equipment and personnel from hazardous overpressure situations. These valves provide a fast and reliable method for pressure relief in various systems, including roller shade motor units, chemical processes, and hydraulic operations.

The rupture disk valve acts as a fail-safe component, ensuring that pressure surges do not cause damage or operational interruptions. Their design and effectiveness make them a popular choice in safety-conscious industries.

How a Rupture Disk Valve Operates

A rupture disk valve is essentially a thin, pre-scored membrane held under tension within a valve body. When internal pressure exceeds a specified limit, the disk bursts, allowing the excess pressure to escape safely. This mechanism prevents equipment failure, protecting costly machinery and minimizing risks to personnel.

Unlike mechanical relief valves, rupture disk valves have no moving parts in the pressure-bearing area. This simplicity enhances reliability and reduces the likelihood of malfunctions, making them ideal for critical systems where consistent performance is required.

Types of Rupture Disk Valves

Forward-Acting Disks

Forward-acting rupture disk valves are designed to burst when pressure pushes directly against the diaphragm. They provide full-flow capacity and are commonly installed in pipelines, tanks, and pressurized vessels.

Reverse-Acting Disks

Reverse-acting rupture disk valves are engineered to resist backpressure. They only open when pressure in the forward direction exceeds the rated limit, which is particularly useful in systems with fluctuating pressures or complex piping configurations.

Scored or Slit Disks

Scored and slit rupture disk valves feature rupture disk valve patterns or pre-cut lines that control the rupture process. This ensures predictable bursting behavior and directs pressure release safely, reducing the risk of sudden or uncontrolled events.

Applications of Rupture Disk Valves

Chemical and Petrochemical Industry

Rupture disk valves protect reactors, storage tanks, and pipelines from sudden pressure spikes. They are essential for preventing hazardous spills, leaks, or explosions in chemical plants.

Pharmaceutical Production

In sterile pharmaceutical environments, rupture disk valves ensure that sensitive processes remain safe by releasing pressure without contaminating products or environments.

Power Generation

Turbines, boilers, and piping systems in power plants are vulnerable to pressure fluctuations. Rupture disk valves act as a safeguard, preventing equipment damage and maintaining operational continuity.

Roller Shade Motor Systems

Motorized roller shade systems sometimes use hydraulic or pneumatic actuators that require overpressure protection. Integrating rupture disk valves into these systems prevents malfunction and ensures smooth operation.

Laboratory and Research Equipment

High-pressure experiments in laboratories benefit from rupture disk valves to protect equipment and personnel from sudden pressure excursions during chemical reactions or testing procedures.

See also: Beyond Transcription: 7 Creative Uses for Audio to Text Technology

Advantages of Using Rupture Disk Valves

Quick Response

Rupture disk valves act instantly when pressure exceeds safe limits, making them highly effective in preventing equipment damage.

Reliable and Maintenance-Free Design

The absence of moving parts in the diaphragm area reduces mechanical failure and minimizes routine maintenance requirements.

Wide Range of Material Options

Manufacturers offer rupture disk valves in materials such as stainless steel, nickel alloys, and Hastelloy, providing resistance to corrosive chemicals and extreme operating conditions.

Cost Efficiency

Compared to complex safety mechanisms, rupture disk valves provide an economical and reliable solution for pressure protection.

Selecting the Right Rupture Disk Valve

Pressure Rating

Select a valve with a burst pressure slightly higher than normal operating pressure but below the maximum allowable pressure of the system to ensure effective protection.

Material Compatibility

Ensure the valve material is compatible with the system media and operating environment. Material choice impacts lifespan and performance reliability.

Flow Capacity

The rupture disk valve must be capable of relieving sufficient pressure volume to prevent system damage during overpressure events.

Installation Considerations

Proper orientation, alignment, and compatibility with flanges are critical. Incorrect installation can compromise valve performance and safety.

Installation and Maintenance Guidelines

Proper Installation

Follow the manufacturer’s instructions closely to ensure the valve functions as designed. Misalignment or incorrect fitting can lead to premature rupture or failure to relieve pressure.

Regular Inspection

Periodic inspection for corrosion, wear, or damage is essential. Keeping spare disks ensures that the system can be restored quickly after activation.

Replacement After Activation

Once a rupture disk valve has operated, it must be replaced immediately. Using a valve with an active disk ensures continued safety and system protection.

Compliance and Standards

Rupture disk valves often meet international standards such as ASME, ISO, and API. Certification ensures predictable performance and regulatory compliance, which is especially important in industrial applications like roller shade motor systems and chemical processing plants.

Emerging Innovations

Advanced Materials

New material developments enhance durability, corrosion resistance, and high-temperature performance of rupture disk valves.

Smart Monitoring Integration

Some systems now integrate sensors to monitor pressure in real time, providing alerts and predictive maintenance data to optimize safety.

Environmentally Conscious Designs

Manufacturers are focusing on recyclable materials and eco-friendly designs to reduce environmental impact while maintaining safety performance.

Conclusion

Rupture disk valves are essential safety devices in any high-pressure system. They provide rapid, reliable, and cost-effective protection against overpressure events. By understanding their operation, selecting appropriate materials, and following proper installation and maintenance practices, industries can safeguard equipment, personnel, and operational continuity. From roller shade motor systems to large-scale industrial processes, rupture disk valves remain a critical component in pressure management and safety systems.