Enhancing Production Accuracy with cnc turning service

In the fast-paced manufacturing sector, businesses are constantly seeking reliable ways to enhance precision, reduce costs, and accelerate production timelines. One of the most dependable technologies that meet these demands is the cnc turning service. This advanced machining solution allows companies to create complex, symmetrical parts with a high degree of accuracy, making it an essential process in modern production environments.

Whether it’s aerospace, automotive, or medical device manufacturing, cnc turning service has cemented its importance as a go-to method for delivering consistent, high-quality components. Let’s explore how this service plays a pivotal role in industrial production and why more companies are turning toward it to streamline operations.

What is cnc turning service?

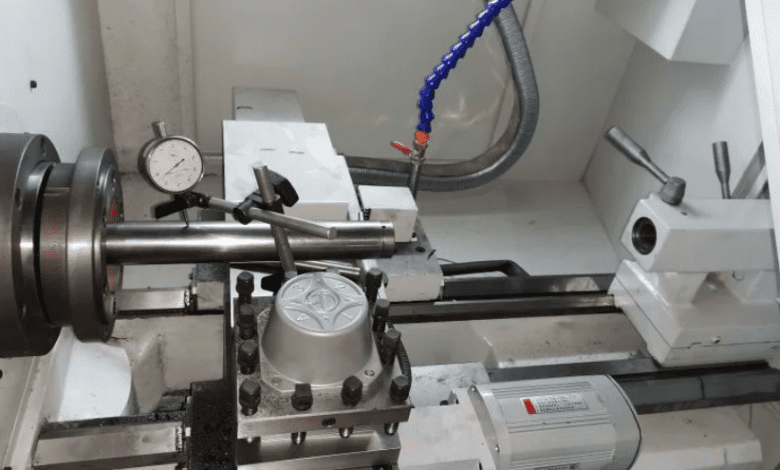

cnc turning service refers to the use of computer numerical control (CNC) machines to rotate a workpiece while a cutting tool removes material to create cylindrical parts. The machine interprets a pre-written digital code (G-code) that directs tool paths, speeds, and positioning, ensuring each part is produced exactly to the engineer’s design.

Unlike manual machining, CNC turning reduces human error, shortens lead times, and enhances uniformity in mass production. The process is highly automated, requiring minimal intervention once set up, and this leads to lower operational costs in the long term.

Main Components of a cnc turning service

To better understand how cnc turning works, it’s important to familiarize yourself with the key components involved:

- Spindle: Holds and rotates the workpiece at variable speeds.

- Tool turret: Houses multiple cutting tools and switches them automatically during the operation.

- Chuck: Clamps the material in place.

- Control panel: Where operators input the CNC code or use interface software to monitor the job.

- Coolant system: Keeps the material and tools from overheating.

This combination ensures the system can cut, shape, and finish parts to exacting standards without constant supervision.

See also: Bathroom Contractor Sacramento for Luxury Spa-Inspired Renovations

Why Manufacturers Choose cnc turning service

1. Unmatched Accuracy

One of the biggest selling points of cnc turning service is its precision. The system can produce parts with extremely tight tolerances, which is critical in sectors like medical implants, aerospace assemblies, and hydraulic systems.

2. Repeatability

When you need thousands of parts that look and function identically, manual processes won’t do. CNC turning guarantees repeatability by following the same instructions with zero deviation, regardless of how many pieces are made.

3. Faster Turnaround

With proper setup, CNC lathes operate at high speeds, often faster than traditional manual lathes. This allows for quicker production cycles and faster delivery to clients.

4. Reduced Waste

Computer-controlled processes use materials efficiently. The CNC turning service minimizes raw material loss through accurate cuts and optimized tool paths, which results in less scrap and reduced costs.

5. Complex Designs Made Simple

Modern CNC turning centers come with multi-axis capabilities and live tooling, making it possible to manufacture parts with intricate shapes, internal cuts, threads, grooves, and more in one operation.

Materials Used in cnc turning service

The flexibility of cnc turning service extends to the range of materials it can handle. Depending on the requirements of the part and industry, the following materials are commonly used:

- Aluminum: Lightweight and corrosion-resistant, ideal for aerospace and electronics.

- Stainless Steel: Durable and strong, used in medical and food-grade applications.

- Brass: Excellent for precision instruments and fittings.

- Titanium: High strength-to-weight ratio, preferred in aerospace and surgical tools.

- Plastics: Nylon, PEEK, and ABS are often used for insulation or lightweight applications.

Every material has unique characteristics, and a skilled cnc turning service provider will understand how to optimize machining strategies based on those traits.

Typical Applications of cnc turning service

Thanks to its adaptability, cnc turning service is used across various industries. Common examples include:

- Automotive: Creating brake rotors, gear blanks, and wheel hubs.

- Aerospace: Crafting engine components, control rods, and housings.

- Medical: Producing bone screws, surgical instruments, and dental parts.

- Defense: Turning ammunition parts, scope mounts, and tactical gear components.

- Industrial Machinery: Manufacturing bushings, spacers, pulleys, and couplings.

Each of these sectors requires reliability, accuracy, and part consistency—all of which CNC turning provides in abundance.

How to Choose a Reliable cnc turning service Provider

When selecting a cnc turning service provider for your project, it’s important to evaluate them on multiple factors:

1. Technical Capability

Do they use state-of-the-art multi-axis CNC lathes? Can they handle live tooling operations? These capabilities are crucial for complex parts.

2. Experience in Your Industry

Working with a provider that understands your sector ensures smoother communication and adherence to relevant standards or certifications (e.g., ISO 9001, AS9100).

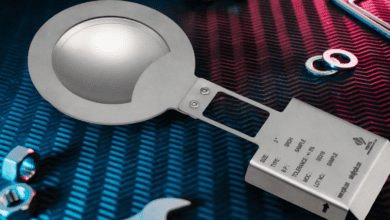

3. Quality Control Process

Top-tier providers have robust quality assurance procedures, including part inspections, surface finish analysis, and final dimensional checks.

4. Customer Support

Clear communication and proactive support are vital, especially when prototyping or custom orders are involved. Choose a company that offers design feedback and keeps you updated throughout the process.

5. Turnaround Time

Look for services that balance speed with quality. Faster delivery shouldn’t compromise part integrity.

The Future of cnc turning service

Technology is advancing rapidly, and so is the cnc turning service industry. Automation, AI integration, and data-driven machining are shaping the future. Machines now include real-time monitoring features, predictive maintenance alerts, and adaptive tool path optimization. These innovations lead to even greater efficiencies, reduced costs, and minimal downtime.

Additionally, as environmental sustainability becomes a global priority, many CNC workshops are adopting greener practices—using biodegradable coolants, reducing energy consumption, and recycling metal chips.

Conclusion

The cnc turning service stands at the heart of high-precision manufacturing. With its ability to produce accurate, repeatable, and complex parts in various materials, it has become a vital tool for industries that demand perfection. Whether you’re launching a new product or optimizing existing production, investing in reliable cnc turning can streamline operations and elevate quality.

As technologies continue to advance, cnc turning will only become more integral to smart manufacturing strategies. Businesses that leverage this powerful solution will undoubtedly position themselves ahead of the competition, armed with precision, speed, and adaptability.